Research and Development Center of Cantoni Group

WORLD CLASS PRECISION OF TESTING

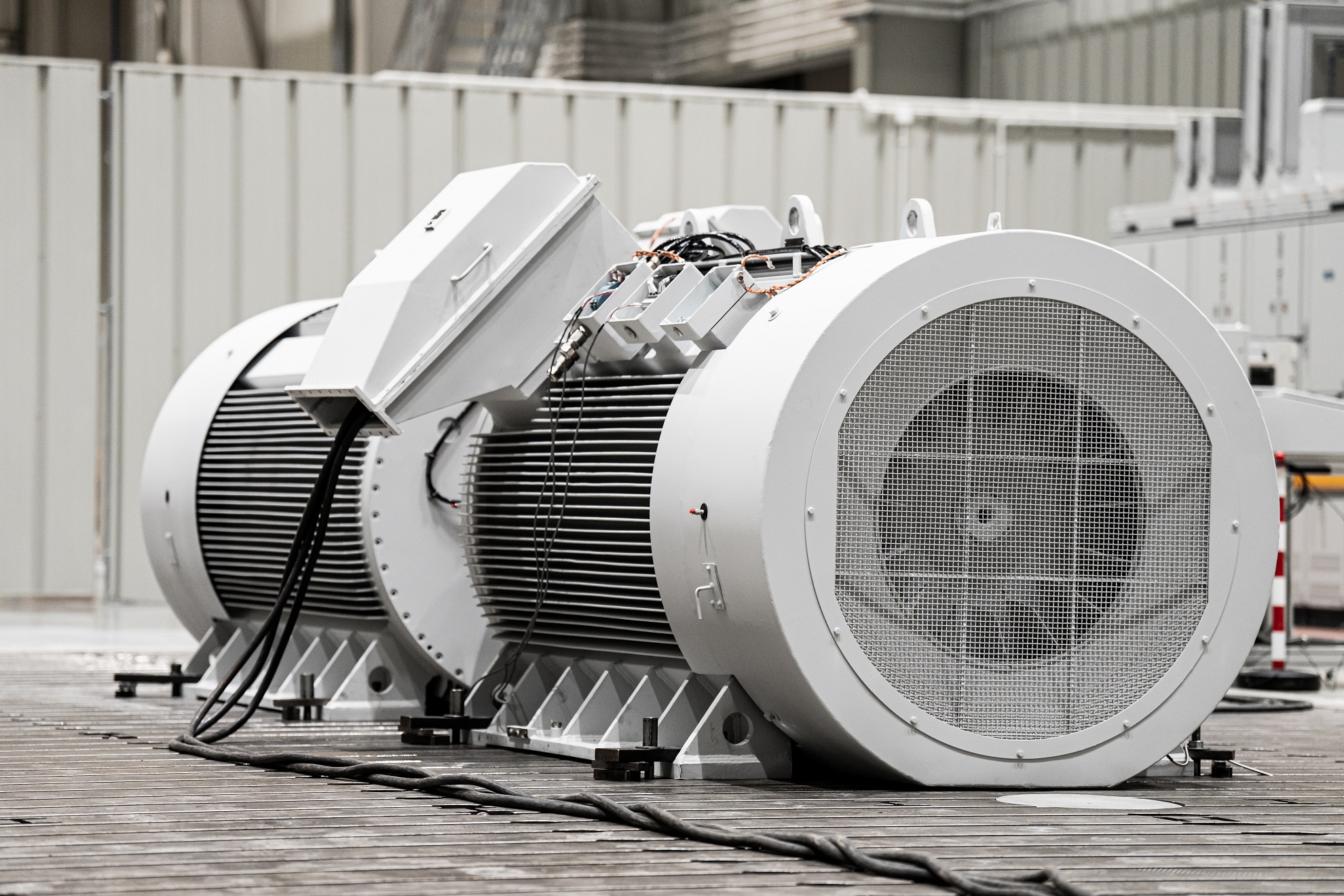

Induction motors are the drivers of the modern world, thus, being a basic part of industrial systems, electric motors must be efficient in its performance. The entire process of motor operation has to be supervised at every stage using precise tools and reliable methods. The need to create the most advanced and innovative motor solutions that meet the requirements of various industries and adjust to specific applications resulted in creation of world class Research and Development Center in Emit S.A. factory in Żychlin, Poland, part of Cantoni Group .

DIFFERENT PURPOSES NEED FLEXIBLE SOLUTIONS

The modern facility enables comprehensive tests of motors in the power range from 50 kW to 6 MW (with continuous power of 3 MW, overload capacity up to 4.6 MW and substitute test for motors up to 6 MW). It allows to specify the electrical characteristics of machines and, most importantly, to accurately determine their efficiency. Precise measurement of parameters allows for the optimization of the operations of electrical machines and the achievement of the potentially highest energy efficiency, which translates into long lifetime of devices, a reduction in the number of failures, more efficient use of resources, and thus also protection of the natural environment.

ADVANCED TECHNOLOGY IN USE

The heart of the R&D Center is a system using state-of-the-art technology of VACON® NXP Danfoss Drives frequency converters . The total power of all power modules is 15 MW and total current that can be obtained from it is 17 kA . The system is liquid-cooled and the total length of the system cabinets, including cooling coils, is 14 meters. The power level of the whole implemented system equals to the needs of a small town with app. 3,000 households . The system was developed, designed and integrated by ELSTA/NEISA in cooperation with experts and engineers from Danfoss .

The Center uses a regenerative power system that significantly reduces energy consumption. Energy circulates all the time in the system, and only the portion needed to make up for losses associated with the operation is drawn from the external grid. In this way, the Center makes it possible to test large and very large motors without using so much power from the grid, which translates into a noticeable reduction in electricity consumption costs and has a positive impact on the environment.

A FULL SPECTRUM OF RESEARCH AND TESTING POSSIBILITIES

The R&D Center is characterized by unprecedented versatility in terms of testing capabilities. It can conduct full tests of the electric motors: from no-load tests to full- load tests to determine the temperature rise and other verifiable parameters such as rated current, power factor or efficiency. In addition to the wide power range, which allows the testing of both very small and very large motors ( from 50 kW up to 6 MW ), it also provides a wide coverage in terms of supply voltages. Motors can be tested at rated voltages from 400 V up to 15 kV . The Center enables tests of both air-cooled (IC411) and water-cooled motors (maximum cooling water flow of up to 550 l/min), as well as motors with force-lubricated sleeve bearings (maximum oil flow of up to 20 l/min). The capabilities in the field of physical characteristics of machines has been expanded. The permissible weight of tested device has been increased to 30 tons , with the total load capacity of test plate up to 60 tons . Thanks to the use of two overhead cranes (15 t and 30 t/15 t) and 72 m2 test plate (6x12 m), the facility can be used to test motors significantly larger than before. The Center is powered by 5 transformers : the main trafo with 4 MVA and additional two multi-tap trafos with 4.19 MVA and two multi-tap trafos with 2.6 MVA. Moreover, the site has been equipped with solutions that enable tests that go beyond the currently set standards, and may come in force in the near future. On site, the motors are analyzed using the partial discharge testing equipment and the rotor cage testing system .

FROM PAST TO THE FUTURE AND BEYOND

The aim of the project has been to establish a structure that would respond to modern needs, enabling comprehensive testing of electric motors used in various industries. State-of the-art technology is also supposed to answer requirements of future, rapidly developing world. The R&D Center, one of the most modern in Europe, is made available not only to EMIT’s clients, but also to other interested parties, including engineers from educational institutions who would like to use its capabilities in their educational and laboratory activities. The project has been co-financed by the European Union through the European Regional Development Fund.

For better picture of our R&D center please have a look on our movie.